Media Sharing

Get More from ICL Directly to Your Inbox

Premier visibility for railcar tracking & management

Trusted 3PL expertise for finished vehicle logistics

End-to-end visibility for finished vehicle shippers

Turnkey solution to manage your yard operations

Optimize or design your transportation network with ease

Streamline your load for maximum efficiency

Even more custom service solutions to support all your logistics needs

We're proud to be a leader in product visibility and invoice auditing solutions throughout the logistics supply chain. Learn more.

Looking to join our team of award winning experts? Check out our open positions now.

We want to hear from you! Get in touch with us today.

For the fine print on our privacy policy, cookies and data, & more.

See how we keep your data safe with certified security practices, secure systems, and constant monitoring.

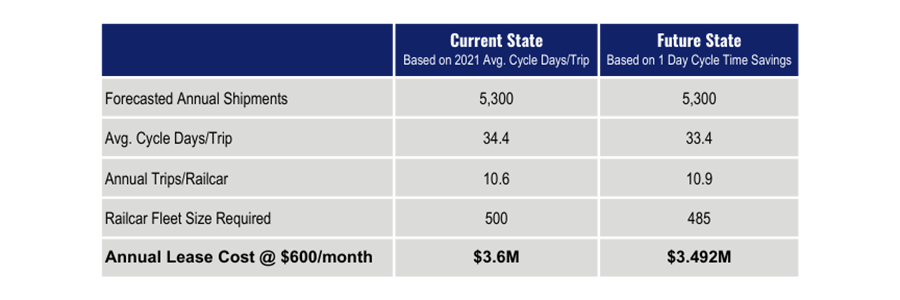

Railcars are expensive assets to own or lease. Rail companies should invest with a clear ROI in all business decisions, yet a high percentage of railcars in North America are not fully utilized. Why does this occur, what is the cost to the shipper, and how can shippers reduce their total asset costs by optimizing railcar utilization?

The average cycle time in North America in 2021 was 34.4 days, or rather, each railcar in the North American fleet made 10.6 full trips in the year, less than one revenue movement per month!

![]()

Transportation, last-mile planning, and paperwork delays can result in shippers over-sizing the rail fleet to meet the projected sales for next year.

Provide ETA reports to receivers automatically to plan in advance for unloading.

Shippers should consider contractually agreed upon times to order in, unload, and release private railcars to incent faster cycle times.

A modern railcar tracking system can alert the logistics team when railcars aren’t moving according to plan.

ICL’s Rail Shipment Visibility Portal (RSVP) offers the following notifications:

The railcar management team can focus their time on analyzing data and optimizing the fleet by automating standard operational reports, such as pipeline reports.

Have discussions with railroads that help resolve problems. Analyze the entire loaded and empty trip, everyone’s railroad’s performance, and location-specific dwell trends so the freight team can have more productive discussions with the railroads on opportunities to improve.

Are you looking to optimize your rail fleet? ICL offers software and 3PL services to help shippers reduce the cost and complexity in shipping by rail, contact us to learn more.

Are you actively shopping for a rail fleet management solution? Read our “How to Select a Railcar Tracking System of Rail TMS” ebook”