As the automotive industry embraces its responsibility to combat climate change, reducing greenhouse gas (GHG) emissions in finished vehicle logistics has become a top priority. This case study explores the steps required to achieve carbon neutrality within the outbound supply chain and highlights the role of data-driven solutions in supporting sustainability goals.

Setting the Stage: Climate Goals and Industry Commitments

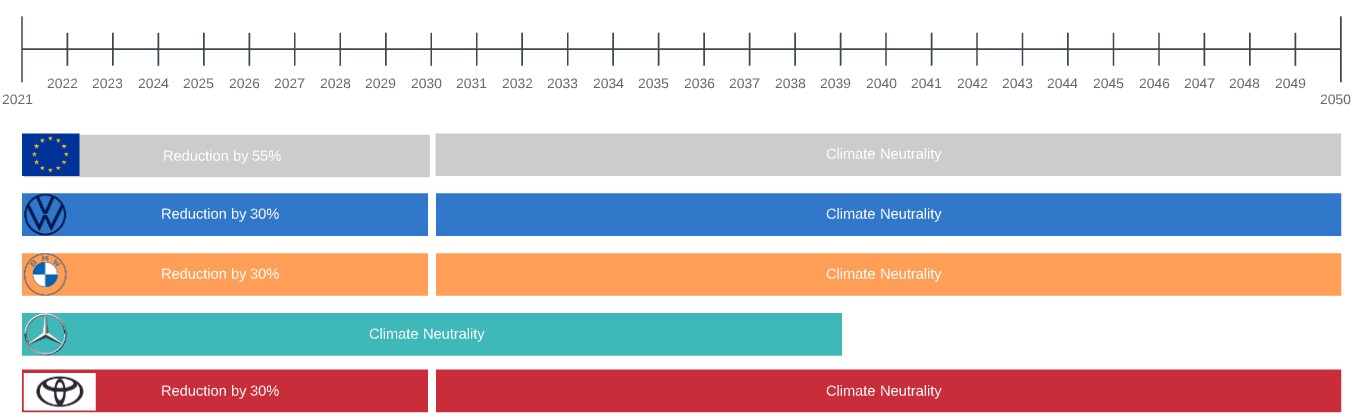

The European Union’s ambitious “Fit for 55” legislative package sets a clear roadmap: reduce GHG emissions by 55% from 1990 levels by 2030 and achieve climate neutrality by 2050. The automotive industry, a focal point of these regulations, must significantly lower emissions from vehicles and road freight transport.

Leading automakers have aligned with these objectives. While many aim for climate neutrality by 2050, some, such as Daimler, target even earlier deadlines, like 2039. Achieving these goals requires addressing all emissions across the supply chain.

Understanding Emissions:

Scope 1, 2, and 3

To effectively reduce emissions, companies must understand where they originate:

- Scope 1: Direct emissions from the company’s operations.

- Scope 2: Emissions from purchased electricity or energy.

- Scope 3: Indirect emissions, such as those from third-party logistics providers and transportation partners.

For automotive manufacturers (OEMs), the majority of logistics-related emissions fall under Scope 3, making collaboration with partners and standardized data reporting essential.

Steps to Carbon Neutrality in Finished Vehicle Logistics

- Collecting Comprehensive Data

Reliable data forms the backbone of any emission reduction strategy. OEMs must track metrics such as miles traveled, vehicle loads, and emissions from storage and transportation.- Solution: Implement a modern tracking system, like ICL’s Vehicle Logistics Management System (VLMS), to provide end-to-end visibility across all logistics providers.

- Analyzing Emissions and Setting Benchmarks

Calculating emissions with internationally recognized frameworks, such as the Global Logistics Emission Council (GLEC) Framework, ensures comparability and accuracy. This analysis highlights areas with the greatest potential for reductions. Find out more: What is the GLEC Framework? – How to implement items | Smart Freight Centre - Optimizing Logistics Networks

With data insights, companies can identify opportunities to reduce emissions by:- Minimizing empty miles through optimized routing.

- Investing in energy-efficient transport modes such as rail or electric vehicles (EVs).

- Streamlining storage processes to reduce waste.

- Implementing Reduction Measures

Targeted initiatives may include upgrading fleets to lower-emission vehicles or improving transloading efficiency. Technology investments, such as emissions tracking systems, further enable data-driven decision-making. - Verifying Savings and Offsetting Remaining Emissions

Regularly re-evaluating and verifying emission reductions ensures ongoing progress. Remaining emissions can be offset using recognized carbon offset programs, closing the gap to full carbon neutrality.

Overcoming Challenges

While the roadmap to Net Zero is clear, challenges persist:

- Data Consistency: OEMs and logistics providers must collaborate to standardize data collection and reporting.

- Cost Considerations: Investments in emission-reducing technologies and fleet upgrades must balance sustainability with profitability.

- Operational Complexity: Managing emissions across global supply chains requires robust systems that aggregate data from multiple sources.

The Role of ICL’s VLMS in Supporting Carbon Neutrality

ICL’s Vehicle Logistics Management System (VLMS) provides the tools needed to address these challenges:

- Data Aggregation and Validation: VLMS consolidates emissions data from all logistics providers, ensuring accuracy and consistency.

- Real-Time Visibility: End-to-end transparency allows OEMs to monitor progress and make informed adjustments.

- Advanced Analytics: Predictive tools highlight inefficiencies and optimize network performance, reducing unnecessary emissions.

- Custom Reporting: Flexible dashboards align with international frameworks, including the GLEC, enabling clear communication of results.

Conclusion: Collaboration for a Greener Future

The journey to Net Zero is long but achievable. By leveraging advanced logistics technologies, such as ICL’s VLMS, the finished vehicle logistics industry can align with climate goals while maintaining profitability. Collaboration across OEMs, logistics providers, and technology partners is essential to unlocking the full potential of emissions reductions.

For more information on how ICL can support your sustainability goals, contact us or download our guide on GHG emissions in finished vehicle logistics. Together, we can drive the industry toward a greener future.