Case Study: Driving CO2 Reductions in Finished Vehicle Logistics

With climate change at the forefront of global discussions, reducing greenhouse gas (GHG) emissions in finished vehicle logistics has become a critical priority. The logistics and automotive sectors, responsible for significant CO2 emissions, are under increasing pressure to align with stringent regulations and ambitious climate goals. This case study explores how companies can tackle CO2 reductions in the finished vehicle logistics industry and highlights strategies to achieve sustainability targets.

The Challenge: Rising Climate Demands on Logistics

The logistics transport sector accounts for over a quarter of total GHG emissions in the EU and the US, second only to energy generation. Among the various modes of transportation, road transport generates the majority of emissions, while rail—due to its electrification—contributes comparatively less.

Share of GHG Emissions in the Logistics Industry

Source: EEA-Europa

The European Union’s Green Deal sets the ambitious goal of achieving complete climate neutrality by 2050, requiring sectors like logistics and automotive to significantly cut emissions. For the finished vehicle logistics industry, this dual pressure of reducing emissions and meeting customer demand necessitates actionable strategies.

Scopes of Emissions in Finished Vehicle Logistics

Source: ICL Systems

GHG emissions in the logistics supply chain are divided into three key categories:

- Scope 1 (Direct Emissions): Emissions generated by operations under the company’s control, such as fleet vehicles.

- Scope 2 (Indirect Energy Emissions): Emissions from the generation of purchased electricity used in logistics operations.

- Scope 3 (Indirect Emissions): Emissions from third-party logistics providers, supply chain partners, and other external sources.

WHAT ARE THE THREE SCOPES OF EMISSIONS? LEARN MORE HERE.

In finished vehicle logistics, most emissions fall under Scope 3, requiring collaboration between Original Equipment Manufacturers (OEMs) and logistics service providers to ensure effective tracking and reductions.

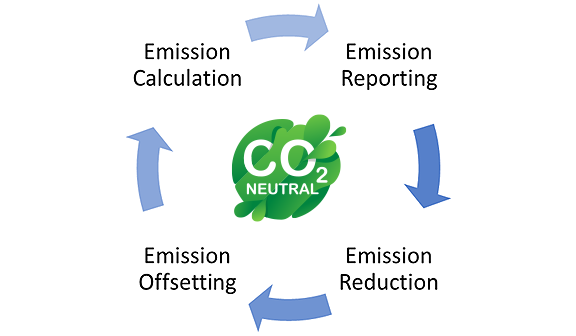

Steps to Reducing CO2 in Finished Vehicle Logistics

Source: ICL Systems

1. Accurate Data Collection

The foundation for any CO2 reduction strategy is comprehensive and accurate data. Key metrics include:

-

- Vehicle weight and load capacity

- Transport distances

- Emissions from storage and idle times

Solution: Leveraging advanced tracking systems like ICL’s Vehicle Logistics Management System (VLMS) provides real-time visibility and ensures precise data aggregation across the supply chain.

2. CO2 Footprint Calculation

Emissions must be calculated for every segment of the logistics network, including road, rail, sea, and storage. A uniform methodology ensures consistency and comparability.

Framework: The Global Logistics Emission Council (GLEC) Framework offers a standardized approach for calculating and reporting emissions, aligning stakeholders on clear goals.

3. Network Optimization

Identifying inefficiencies in the supply chain is key to achieving meaningful reductions. Strategies include:

-

- Minimizing empty miles through optimized routing.

- Transitioning to lower-emission transportation modes, such as electrified rail or alternative-fuel trucks.

- Streamlining storage and transloading processes.

4. Emission Reductions and Offsetting

Implementing targeted measures, such as fleet upgrades and energy-efficient operations, can reduce direct emissions. Any remaining emissions can be offset through recognized carbon offset programs.

5. Continuous Improvement

Achieving net-zero emissions requires regular re-evaluation of data and strategies. Transparent reporting helps track progress and identify new opportunities for reduction.

Overcoming Barriers to CO2 Reduction

While reducing CO2 emissions is essential, the process presents challenges:

- Data Consistency: Without uniform reporting standards, coordinating emission reductions across multiple logistics providers can be complex.

- Cost Concerns: Investments in greener technologies and processes must balance sustainability with profitability.

- Operational Complexity: Managing emissions across global supply chains requires robust tools capable of aggregating data and providing actionable insights.

How ICL’s VLMS Supports CO2 Reductions

ICL’s Vehicle Logistics Management System (VLMS) is designed to address these challenges, empowering logistics teams to achieve sustainability goals:

- Comprehensive Data Collection: VLMS aggregates emissions data from all supply chain partners, ensuring accuracy and visibility across the network.

- Real-Time Insights: The system provides end-to-end visibility, enabling stakeholders to monitor performance and identify inefficiencies.

- Custom Reporting: Flexible dashboards and analytics align with frameworks like GLEC, simplifying emissions tracking and reporting.

- Optimization Tools: Predictive analytics highlight areas for improvement, such as route optimization and reduced idle times, to minimize CO2 output.

A Collaborative Path to Climate Neutrality

Currently, there is no standardized framework specifically tailored to the unique requirements of vehicle logistics. However, the Global Logistics Emission Council (GLEC) Framework, established in 2014 by the Smart Freight Centre (SFC), comes closest to meeting these needs. This internationally recognized methodology provides guidelines for calculating and reporting logistics emissions, integrating approaches like DIN EN 16258 and the GHG Protocol.

Interested in learning more about reducing emissions in finished vehicle logistics?

Explore our GHG and FVL Fact Sheet for practical insights and actionable steps.

For further details on the GLEC Framework and how it supports emission tracking in finished vehicle logistics, feel free to contact us directly.

Learn More About Finished Vehicle Logistics

Be sure to check out the second article in our case study series on GHG Emissions, where Johannes Koch discusses the challenges and strategies on The Road to NetZero. Read it here!