Media Sharing

Get More from ICL Directly to Your Inbox

Premier visibility for railcar tracking & management

Trusted 3PL expertise for finished vehicle logistics

End-to-end visibility for finished vehicle shippers

Turnkey solution to manage your yard operations

Optimize or design your transportation network with ease

Streamline your load for maximum efficiency

Even more custom service solutions to support all your logistics needs

We're proud to be a leader in product visibility and invoice auditing solutions throughout the logistics supply chain. Learn more.

Looking to join our team of award winning experts? Check out our open positions now.

We want to hear from you! Get in touch with us today.

For the fine print on our privacy policy, cookies and data, & more.

See how we keep your data safe with certified security practices, secure systems, and constant monitoring.

We sat down with Frank Agrusa, Director, Product Development & Innovation, on what solutions we can use to support a frictionless exchange of data from any logistics provider or the vehicle itself as well as the future of logistic data management.

Here at ICL, we want to help our customers solve their data problems, so it depends on what they want to do. Getting location information is of utmost importance to supply chain visibility, and the timeliness of that data is equally important, understanding the custodial transfer that goes through the network and which information we may not need as often. For example, tracking a vehicle for final mile delivery, if you are not processing and updating that position every 5 mins with an exact lat/long, you will not have an accurate picture of the vehicle.

It ultimately depends on the use of that data, but timeliness in receiving and processing it is always of utmost importance.

Standardization has always been the biggest challenge in sharing and exchanging data. As much as we want to be flexible in accepting any data, maintaining different formats/types inherently becomes more expensive.

Manual data is the most antiquated format, but still, at times, there is no way around using it. We have several web screens that allow us to upload these manual spreadsheets and get the data into our system as quickly as possible. The goal here is to move anything manual to something automated as soon as possible. Still, flexibility in accepting all data sources is the only way to paint a complete picture. Old school technology such as EDI, X12, or even flat files is a step above manual but still hinders the limits of real-time processing. Many of the files we receive are down to every 15 minutes, so we have come a long way in improving vehicle visibility, but this format isn’t quite at the API real-time transactions that we would prefer. What is nice about these types of files is that they have a very structured format making them easy to define within a system and making it even easier to validate whether the data is following that format.

Regardless of technology, delivering the data collected as close to real-time to the systems that need it is of utmost importance to achieve the predictive and prescriptive analysis that our modern supply chain needs.

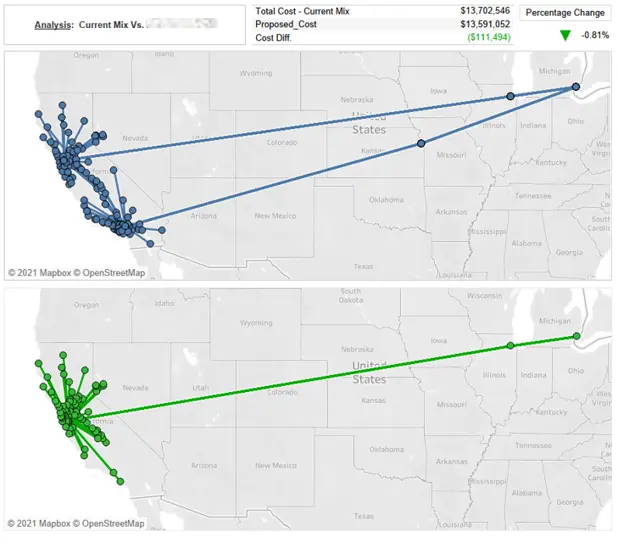

See below an example cost comparable map of current and proposed costs, over different transport modes available.

One of the issues in getting to the Amazon-type ETA tracking is that the finished vehicle logistics chain wasn’t necessarily designed to achieve accuracy. When you own the supply chain from start to finish and running fixed routes every day, scheduling when the deliveries will occur is much more simplistic, and this is cost-prohibitive for the most part in the automotive finished vehicle world.

Another problem we face is that some vehicle carriers may feel that supplying too much data can expose them to questions they may not want to answer. The key to collaboration is showing how it will be a win/win for everyone involved. Suppose we can provide accurate forecasts directly to a truck carrier’s TMS and show how this will improve their ability to schedule loads; in that case, they may be more willing to provide last-mile vehicle data directly from the truck’s ELD unit.

My vision for the future for a vehicle supply chain is to predict and prescribe changes throughout the network based on simulation modelling with different volumes, different costs and updating this data in real-time. The picture always reflects the complete optimization of all the relevant variables. Having a good visibility picture with little to no black holes has been the tricky part.

We are currently working with a customer to collect damage data throughout their network (inspection company, truck carriers, and yards). They have business analytic dashboards of precisely those types of criteria (where the damage occurred, what mode). They use the AIAG codes to describe the damage, and we track by where it is first reported so we can entirely do those investigations on how to lessen damage at those places. This is a step in the right direction for the future of logistics information management.

For more on Franks’ insights into data-driven logistics and how ICL works on flexible solutions to support a frictionless exchange of data, you can check out his panel discussion with Steve Jernigan from Nissan at Finish Vehicle Logistics North America Live

We offer products and services that meet the needs of many different areas of the logistics industry. For more information on logistic reporting applications and how they can suit the needs of your supply chain, explore our software solutions.